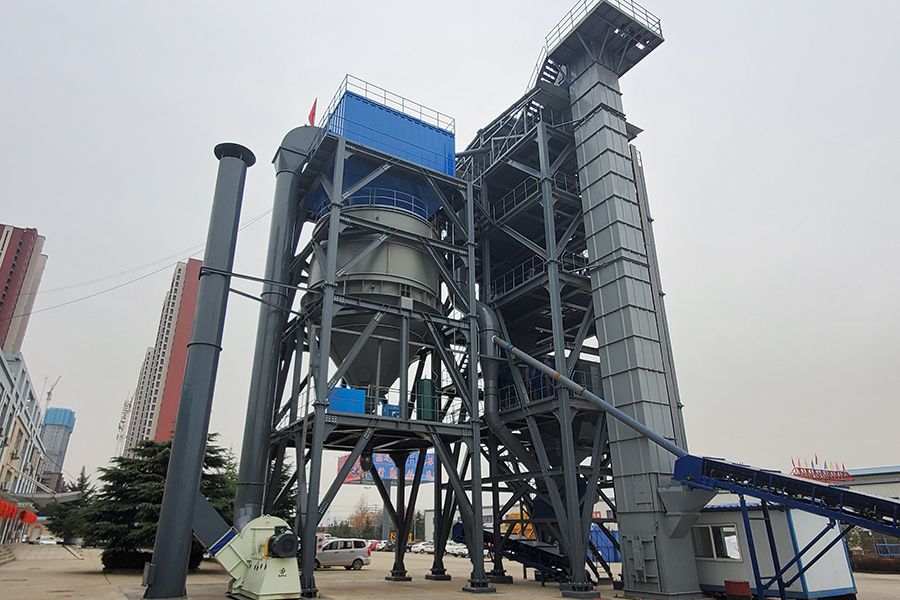

HZSL High efficiency Eco environmental protection sand making plant

Advantages

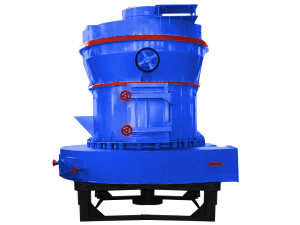

1.The system use t CC series high efficient centrifugal impactor sand making machine, high efficiency, low investment.

2.Particle shape is multi cubic body, good occlusion, effectively improve the strength of concrete and the capacity of the concrete pump.

3.Low system power consumption (energy consumption reduced by 50% or so), high capacity production capacity (double).

4.The granularity distribution is uniform, gradation is continuous and stable.

5.For the linear grading, the sand can save 30-70 kg per cubic meter for C30 cement than natural sand.

6.Stone powder can be controlled between 3-15%.

7.Fineness modulus is adjustable between 2.2 to 3.0 steadily.

8.Dust zero emissions, low noise, no vibration.

9.Cover an area smaller, intensive design, modular assembly, flexibility is strong, adapt to sand making and shaping for all kinds materials.

10.CC series high efficient centrifugal impact sand making machine adopts double cavity sino-german technology design.The screening system integrates the air screening and dry screening technology,which has a higher efficiency.At the same time,it also reduces the problem of screen stoppage.The wear-resistant parts uses the high strength alloy,which pro-long the using life and efficiently reducing the time for stop and recondition.

11.High environmental standards, the whole system adopts closed transportation, production, and the design of negative pressure dust removal, fully comply with national environmental requirements.

Product Parameter

|

Model |

Main machine |

Vibrating screen |

Input size |

Output ≤5MM |

Powder content |

Total power |

Control system |

|

HZSL60 |

ZS1624 |

2YK1860 |

0-100mm |

60t/h |

3-15%Adjustable |

≈330 |

PLC control or centralized control |

|

HZSL150 |

ZS2028 |

2YK2470 |

150t/h |

≈633 |

|||

|

HZSL200 |

ZS2233 |

2YK2870 |

200t/h |

≈863 |

1.The system use t CC series high efficient centrifugal impactor sand making machine, high efficiency, low investment.

2.Particle shape is multi cubic body, good occlusion, effectively improve the strength of concrete and the capacity of the concrete pump.

3.Low system power consumption (energy consumption reduced by 50% or so), high capacity production capacity (double).

4.The granularity distribution is uniform, gradation is continuous and stable.

5.For the linear grading, the sand can save 30-70 kg per cubic meter for C30 cement than natural sand.

6.Stone powder can be controlled between 3-15%.

7.Fineness modulus is adjustable between 2.2 to 3.0 steadily.

8.Dust zero emissions, low noise, no vibration.

9.Cover an area smaller, intensive design, modular assembly, flexibility is strong, adapt to sand making and shaping for all kinds materials.

10.CC series high efficient centrifugal impact sand making machine adopts double cavity sino-german technology design.The screening system integrates the air screening and dry screening technology,which has a higher efficiency.At the same time,it also reduces the problem of screen stoppage.The wear-resistant parts uses the high strength alloy,which pro-long the using life and efficiently reducing the time for stop and recondition.

11.High environmental standards, the whole system adopts closed transportation, production, and the design of negative pressure dust removal, fully comply with national environmental requirements.

|

Model |

Main machine |

Vibrating screen |

Input size |

Output ≤5MM |

Powder content |

Total power |

Control system |

|

HZSL60 |

ZS1624 |

2YK1860 |

0-100mm |

60t/h |

3-15%Adjustable |

≈330 |

PLC control or centralized control |

|

HZSL150 |

ZS2028 |

2YK2470 |

150t/h |

≈633 |

|||

|

HZSL200 |

ZS2233 |

2YK2870 |

200t/h |

≈863 |