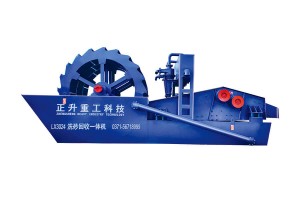

High efficiency Superfine rotor powder concentrator

Structural Composition

1: Spindle motor; 2: damping fan; 3: building base

Working Principle

It is designed by applying the plane vortex theory to the cyclone separator on the basis of the rotor separator. The practice shows that the powder separation efficiency is more than 85%; The fineness adjustment is flexible and convenient, and the performance is reliable.

① The particle size distribution of finished products is concentrated, the particle grading is more reasonable, and the product quality is significantly improved.

② It is easy to operate and the fineness is easy to adjust.

③ The unit power consumption of the system is about 30% lower than that of the traditional circular flow grinding.

④ The anti condensation effect is reliable and can adapt to various climatic environments.

⑤ It adopts dust-proof shock-absorbing fan, equipped with shock-absorbing base, which can be directly supported by steel frame, which is particularly convenient for installation.

Product Parameter

|

Model |

Product fineness 0.075(%) |

Speed(rpm) |

Capacity(t/h) |

Power(KW) |

|

ZSXF250 |

0-5 |

150-300 |

15-30 |

5.5 |

|

ZSXF350 |

0-5 |

130-280 |

30-55 |

7.5 |

|

ZSXF500 |

0-5 |

120-260 |

50-80 |

7.5 |

|

ZSXF750 |

0-5 |

110-250 |

80-110 |

11 |

|

ZSXF1000 |

0-5 |

100-230 |

110-150 |

15 |

|

ZSXF1250 |

0-5 |

90-210 |

150-200 |

18.5 |

|

ZSXF1500 |

0-5 |

80-200 |

200-250 |

22 |

|

ZSXF2000 |

0-5 |

70-180 |

240-300 |

30 |

|

ZSXF2500 |

0-5 |

60-160 |

280-350 |

45 |

|

ZSXF3000 |

0-5 |

50-150 |

350-450 |

55 |

|

Model |

Product fineness 0.075(%) |

Speed(rpm) |

Capacity(t/h) |

Power(KW) |

|

ZSXF250 |

0-5 |

150-300 |

15-30 |

5.5 |

|

ZSXF350 |

0-5 |

130-280 |

30-55 |

7.5 |

|

ZSXF500 |

0-5 |

120-260 |

50-80 |

7.5 |

|

ZSXF750 |

0-5 |

110-250 |

80-110 |

11 |

|

ZSXF1000 |

0-5 |

100-230 |

110-150 |

15 |

|

ZSXF1250 |

0-5 |

90-210 |

150-200 |

18.5 |

|

ZSXF1500 |

0-5 |

80-200 |

200-250 |

22 |

|

ZSXF2000 |

0-5 |

70-180 |

240-300 |

30 |

|

ZSXF2500 |

0-5 |

60-160 |

280-350 |

45 |

|

ZSXF3000 |

0-5 |

50-150 |

350-450 |

55 |