-

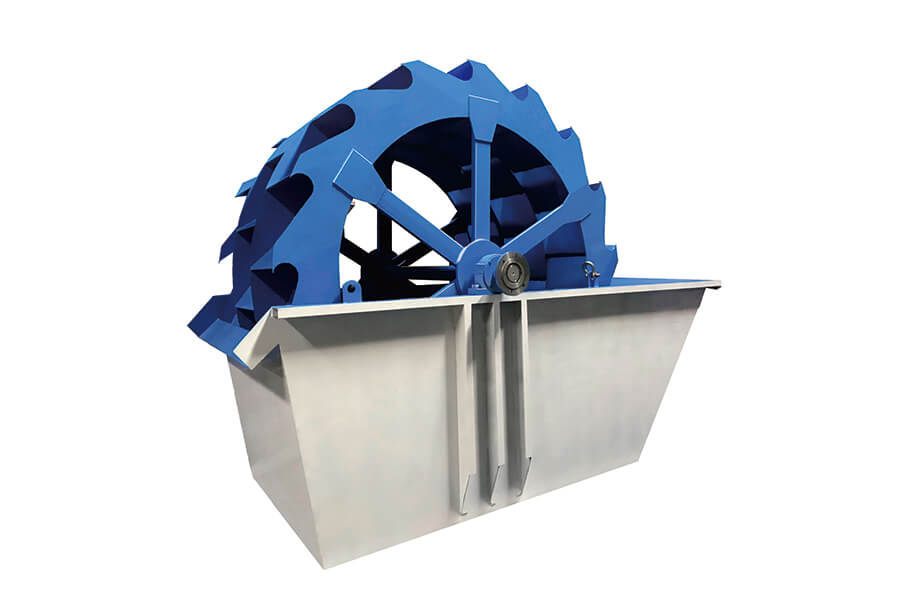

XSD Bucket Wheel Sand Washing Machine

It can remove the impurities covering the surface of sand and gravel, and destroy the water vapor layer covering sand particles, so as to facilitate dehydration and play the role of efficient sand washing.

● Input Size: 0-10mm

● Capacity: 20-150TPH

● Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore etc.

explore

-

LX Series Spiral Sand Washing Machine

Spiral sand washing machine is a conventional sand washing machine, which mainly stirs the sand and stone through the spiral device in the equipment, so that the soil and water in the sand and stone are mixed and discharged from the flow port on the equipment, while the sand and stone are gradually screened under the action of the spiral device and discharged from the discharge port, so as to realize the cleaning and screening effect of sand and stone.

● Feed particle size: ≤ 10mm

● Processing capacity: ≤ 40-350TPH

explore

-

PXJ Series High-Efficiency Fine Crusher

PXJ series high-efficiency fine crusher, also known as impact fine crusher and new fine crusher. The machine has a wide range of uses. It is the most effective, practical and reliable gravel machine at present. It is especially suitable for the fine and medium crushing of abrasive, refractory, cement, quartz sand, steel sand and other hard and brittle materials. It is an efficient and energy-saving gravel sand making equipment, which saves 50% energy compared with the traditional fine crusher.

● Input Size: ≤190 mm

● Capacity: 20-310 TPH

explore

-

DMC Series Pulse-jet bag filter

DMC Series Pulse-jet bag filter is a new generation product developed on the basis of the original DMC pulse dust collector, drawing lessons from foreign advanced technology and combined with the actual situation of small air volume single machine dust collector in China.

The machine adopts high-pressure (0.5-0.7mpa) large flow pulse valve and Venturi tube strip filter bag jet ash cleaning technology, which has the advantages of high ash cleaning rate, especially on-line ash cleaning.

The continuous operation of the dust collector overcomes the shortcomings of the original mechanical vibration and shutdown, and can be widely used in metallurgy, mining, chemical industry, building materials, non-metallic processing, grain, pharmaceutical and other fields.

And the machine adopts pulse injection controller, which can realize automatic control of ash cleaning.

explore

Contact Us Now

Submitting your email address can ensure that you receive our latest consultation as soon as possible!

Inquiry now

*We will not share your personal information

Inquiry now

*We will not share your personal information