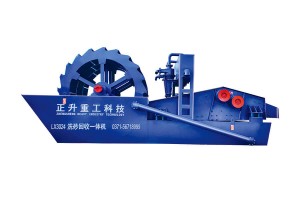

LX Series Spiral Sand Washing Machine

Machine Construction

The spiral sand washing machine is composed of tank body, reducer, motor, shaft, spiral blade and support.

Working Principle

With the help of the principle that the specific gravity of solid particles is different, so the settling speed in liquid is different, screening is carried out

1. The processing capacity is large. Because the sand washing principle of the screw sand washing machine is not "fishing" with a bucket, its processing capacity has been greatly improved.

2. The energy utilization rate is higher, which reduces the energy consumption loss caused by the wheel bucket in the lifting process, so that the energy can be used effectively.

3. The wear of some parts is reduced. The spiral sand washer does not need to increase the screen, so the loss of the screen is reduced and the service life of the equipment is prolonged.

Product Parameter

|

Model |

Number of screw |

Screw diamerer(MM) |

Length of Sink (MM) |

Feed size (MM) |

Speed (R/MIN) |

Capacity (T/H) |

Water consumptionH(m³/H) |

Power (KW) |

|

LXS-610 |

1 |

610 |

7225 |

≤10 |

32 |

40-50 |

6-63 |

7.5 |

|

LXS-760 |

2 |

762 |

7620 |

26 |

50-75 |

9-63 |

11 |

|

|

LXS-920 |

1 |

920 |

7585 |

21 |

100 |

10-80 |

11 |

|

|

2LXS-920 |

2 |

920 |

7585 |

21 |

200 |

20-160 |

11x2 |

|

|

LXS-1120 |

1 |

1120 |

9750 |

17 |

175 |

20-150 |

18.5 |

|

|

2LXS-1120 |

2 |

1120 |

9750 |

17 |

350 |

40-300 |

18.5x2 |

|

Model |

Number of screw |

Screw diamerer(MM) |

Length of Sink (MM) |

Feed size (MM) |

Speed (R/MIN) |

Capacity (T/H) |

Water consumptionH(m³/H) |

Power (KW) |

|

LXS-610 |

1 |

610 |

7225 |

≤10 |

32 |

40-50 |

6-63 |

7.5 |

|

LXS-760 |

2 |

762 |

7620 |

26 |

50-75 |

9-63 |

11 |

|

|

LXS-920 |

1 |

920 |

7585 |

21 |

100 |

10-80 |

11 |

|

|

2LXS-920 |

2 |

920 |

7585 |

21 |

200 |

20-160 |

11×2 |

|

|

LXS-1120 |

1 |

1120 |

9750 |

17 |

175 |

20-150 |

18.5 |

|

|

2LXS-1120 |

2 |

1120 |

9750 |

17 |

350 |

40-300 |

18.5×2 |