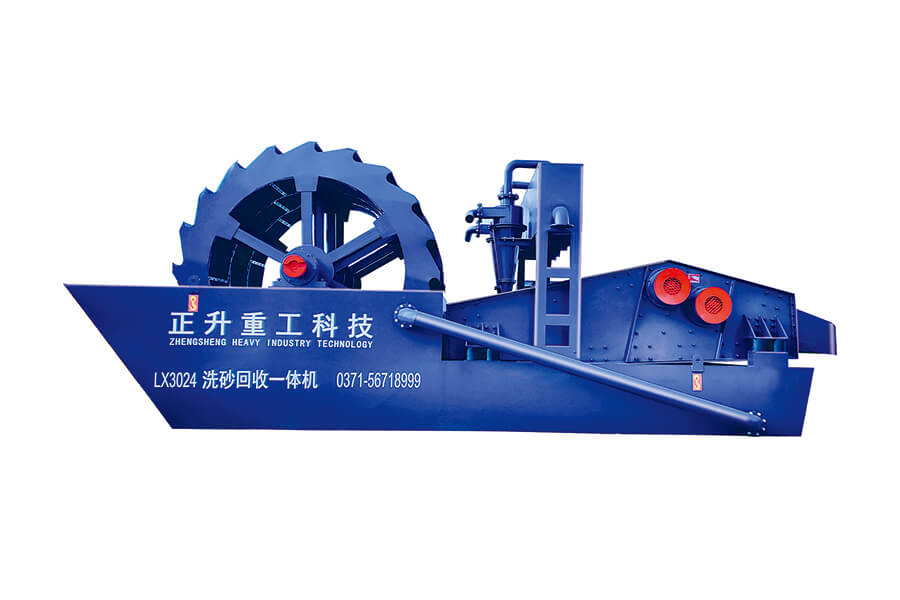

XS series Sand washing and fine sand recovery all-in-one Machine

Machine Construction

It is composed of motor, slurry pump, cyclone, zkr linear vibrating screen, cleaning tank, return box, etc.

Working Principle

The sand water mixture is transported to the cyclone, and the fine sand concentrated by centrifugal classification is supplied to the vibrating screen through the sand setting nozzle. After dehydration by the vibrating screen, the fine sand is separated from water, and a small amount of fine sand and mud return to the cleaning tank through the return tank. When the liquid level of the cleaning tank is too high, it is discharged through the discharge port. The weight concentration of the recovered material of the linear vibrating screen is 70% - 85%. The fineness modulus can be adjusted by changing the pump speed, changing the mortar concentration, adjusting the overflow water and replacing the sand nozzle. So as to complete the three functions of cleaning, dehydration and classification.

Video

Equipment Advantages

① In the traditional wet processing technology of artificial sand, the spiral sand washing machine is used for mud washing and dehydration of artificial sand, and the loss of artificial sand (especially fine sand) can hardly be controlled. The fine sand recovery device can reduce the loss of fine sand and control it within 5 ~ 10%. The problems of high fineness modulus of finished sand and low content of stone powder in artificial aggregate processing system are well solved.

② The vibrating screen adopts polyurethane screen, which has longer service life than other types of screens and is not easy to block holes.

③ The cyclone is lined with polyurethane, which improves the service life of the whole device and can successfully complete slurry concentration, liquid clarification and so on.

④ The fine sand recovery system is large and can recover 85% of the fine particle materials in the total discharge, which has incomparable technical and economic advantages compared with other equipment.

⑤ The fine particles are fully recovered, which reduces the workload of the sedimentation tank and the cleaning cost of the sedimentation tank.

⑥ The fine sand recovery system reduces the natural stacking time of fine materials and can be directly transported to the market.

⑦ Corresponding solutions can be designed according to different requirements of users.

Product Parameter

|

Model |

Impeller diameter (MM) |

Impeller width (MM) |

Sieve plate specification (MM) |

Separator specification (MM) |

Water consumption(m³/H) |

Capacity (T/H) |

Power (KW) |

Overall dimension (MM) |

|

XS2600-35-1224 |

2600 |

1200 |

1200x2400 |

350 |

≤80 |

40-60 |

≈28 |

5600x5200x2700 |

|

XS3016-50-1530 |

3000 |

1600 |

1500x3000 |

250x2 |

≤120 |

60-95 |

≈44 |

6700x5500x2760 |

|

2XS3016-70-1530 |

3000 |

1600 |

1500x3000 |

350x2 |

≤120 |

60-95 |

≈51 |

6700x5500x2760 |

|

XS3024-70-2040D |

3000 |

2400 |

2000x4000 |

350x2 |

≤200 |

80-120 |

≈70 |

8590x5560x3670 |

|

2XS3024-120-2442D |

3000 |

2400 |

2400x4200 |

300x4 |

≤250 |

120-160 |

≈81 |

8590x5560x3670 |

|

XS3624-120-2442D |

3600 |

2400 |

2400x4200 |

300x4 |

≤250 |

150-220 |

≈81 |

9290x6460x4170 |

|

2XS3624-120-2442D |

3600 |

2400 |

2400x4200 |

300x4 |

≤280 |

120-220 |

≈99.5 |

12900x6460x4170 |

① In the traditional wet processing technology of artificial sand, the spiral sand washing machine is used for mud washing and dehydration of artificial sand, and the loss of artificial sand (especially fine sand) can hardly be controlled. The fine sand recovery device can reduce the loss of fine sand and control it within 5 ~ 10%. The problems of high fineness modulus of finished sand and low content of stone powder in artificial aggregate processing system are well solved.

② The vibrating screen adopts polyurethane screen, which has longer service life than other types of screens and is not easy to block holes.

③ The cyclone is lined with polyurethane, which improves the service life of the whole device and can successfully complete slurry concentration, liquid clarification and so on.

④ The fine sand recovery system is large and can recover 85% of the fine particle materials in the total discharge, which has incomparable technical and economic advantages compared with other equipment.

⑤ The fine particles are fully recovered, which reduces the workload of the sedimentation tank and the cleaning cost of the sedimentation tank.

⑥ The fine sand recovery system reduces the natural stacking time of fine materials and can be directly transported to the market.

⑦ Corresponding solutions can be designed according to different requirements of users.

|

Model |

Impeller diameter (MM) |

Impeller width (MM) |

Sieve plate specification (MM) |

Separator specification (MM) |

Water consumption(m³/H) |

Capacity (T/H) |

Power (KW) |

Overall dimension (MM) |

|

XS2600-35-1224 |

2600 |

1200 |

1200×2400 |

350 |

≤80 |

40-60 |

≈28 |

5600x5200x2700 |

|

XS3016-50-1530 |

3000 |

1600 |

1500×3000 |

250×2 |

≤120 |

60-95 |

≈44 |

6700x5500x2760 |

|

2XS3016-70-1530 |

3000 |

1600 |

1500×3000 |

350×2 |

≤120 |

60-95 |

≈51 |

6700x5500x2760 |

|

XS3024-70-2040D |

3000 |

2400 |

2000×4000 |

350×2 |

≤200 |

80-120 |

≈70 |

8590x5560x3670 |

|

2XS3024-120-2442D |

3000 |

2400 |

2400×4200 |

300×4 |

≤250 |

120-160 |

≈81 |

8590x5560x3670 |

|

XS3624-120-2442D |

3600 |

2400 |

2400×4200 |

300×4 |

≤250 |

150-220 |

≈81 |

9290x6460x4170 |

|

2XS3624-120-2442D |

3600 |

2400 |

2400×4200 |

300×4 |

≤280 |

120-220 |

≈99.5 |

12900x6460x4170 |