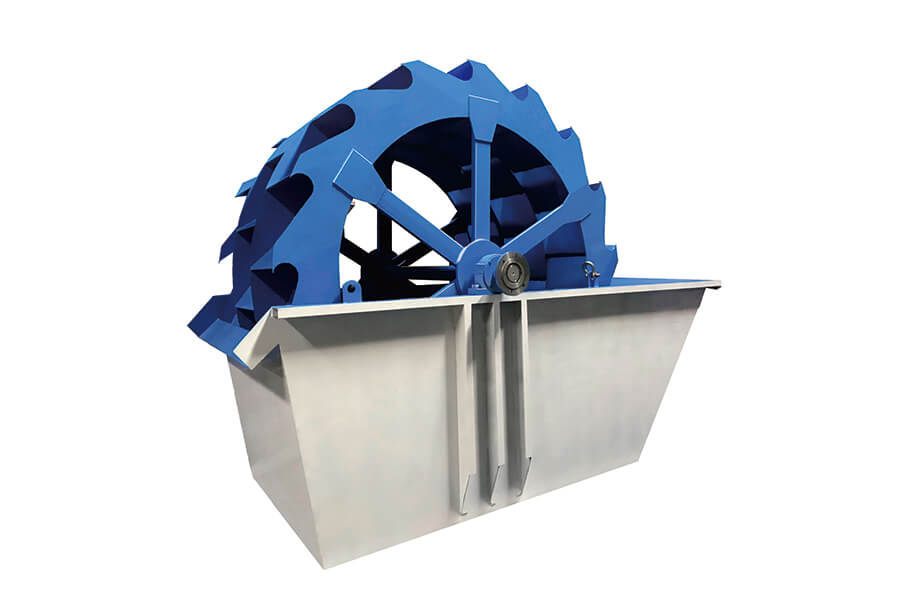

XSD Bucket Wheel Sand Washing Machine

When the sand washing machine works, the motor drives the impeller to rotate slowly after decelerating through the triangular belt, reducer and gear. The sand and stone enter the washing tank from the feed tank, roll under the drive of the impeller, and grind each other to remove the impurities covering the sand and stone surface, and destroy the water vapor layer covering the sand particles, so as to facilitate dehydration. At the same time, add water to form a strong water flow, take away impurities and foreign matters with small specific gravity in time, and discharge them from the overflow outlet washing tank to complete the cleaning function. The clean sand and stone are taken away by the blade, and the later sand and stone are poured into the discharge chute from the rotating impeller to complete the cleaning of sand and stone.

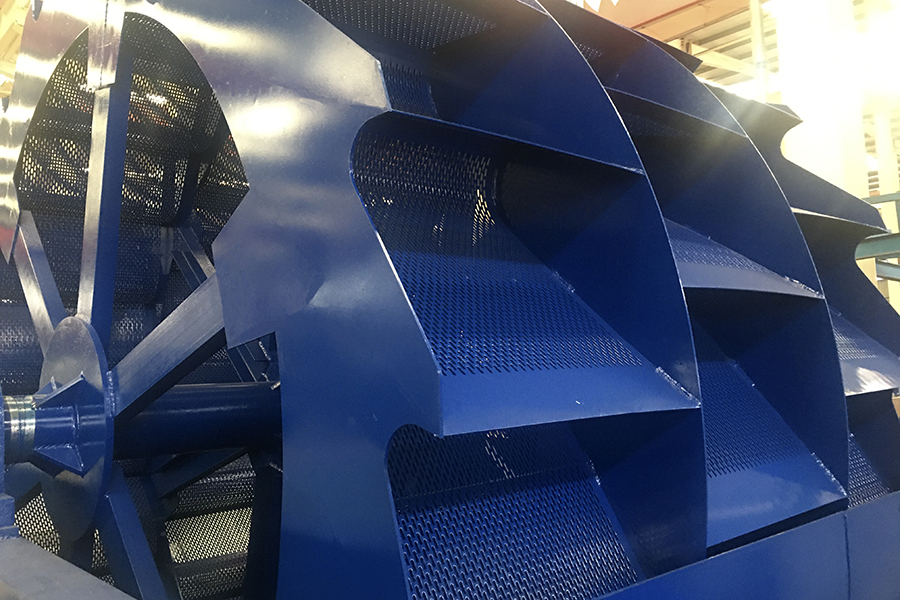

1. Novel structure and good cleaning effect

The novel sealing structure, fully enclosed oil bath transmission device and adjustable overflow weir plate ensure the high efficiency and durability of this series of products, good cleaning and dehydration effect and stable fine-grained products.

2. Good sealing performance, high efficiency and environmental protection

Good structural layout and effective sealing design make the equipment wear less and durable; Low water consumption, low working noise, in line with national environmental protection standards.

3. Simple structure and wide application range

The equipment structure is simple, and the impeller drive bearing device is isolated from water and water receiving materials, which greatly avoids the damage of the bearing caused by water immersion, sand and pollutants. Therefore, it can be applied to various working environments.

4. High cleanliness and low production cost

5. Large processing capacity and low power consumption

Product Parameter

|

Model |

Impeller diameter (MM) |

Feed size(MM) |

Impeller width (mm) |

Bucker quantity |

Speed(R/MIN) |

Capacity (T/H) |

Water consumption(m³/H) |

Motor model |

Power (KW) |

Dimension (MM) |

|

XSD2600 |

2600 |

≤10 |

985x2 |

32 |

1.2 |

20-50 |

10-30 |

Y160L-8 |

7.5 |

3524x2060x2622 |

|

XSD2800 |

2800 |

30-70 |

10-40 |

Y180L-8 |

11 |

3810x2820x2883 |

||||

|

XSD3200 |

3200 |

50-100 |

10-60 |

Y200L-8 |

15 |

3810x2820x3083 |

||||

|

XSD3600 |

3600 |

80-150 |

20-110 |

Y225S-8 |

18.5 |

4456x2479x3688 |

|

Model |

Impeller diameter (MM) |

Feed size(MM) |

Impeller width (mm) |

Bucker quantity |

Speed(R/MIN) |

Capacity (T/H) |

Water consumption(m³/H) |

Motor model |

Power (KW) |

Dimension (MM) |

|

XSD2600 |

2600 |

≤10 |

985×2 |

32 |

1.2 |

20-50 |

10-30 |

Y160L-8 |

7.5 |

3524x2060x2622 |

|

XSD2800 |

2800 |

30-70 |

10-40 |

Y180L-8 |

11 |

3810x2820x2883 |

||||

|

XSD3200 |

3200 |

50-100 |

10-60 |

Y200L-8 |

15 |

3810x2820x3083 |

||||

|

XSD3600 |

3600 |

80-150 |

20-110 |

Y225S-8 |

18.5 |

4456x2479x3688 |