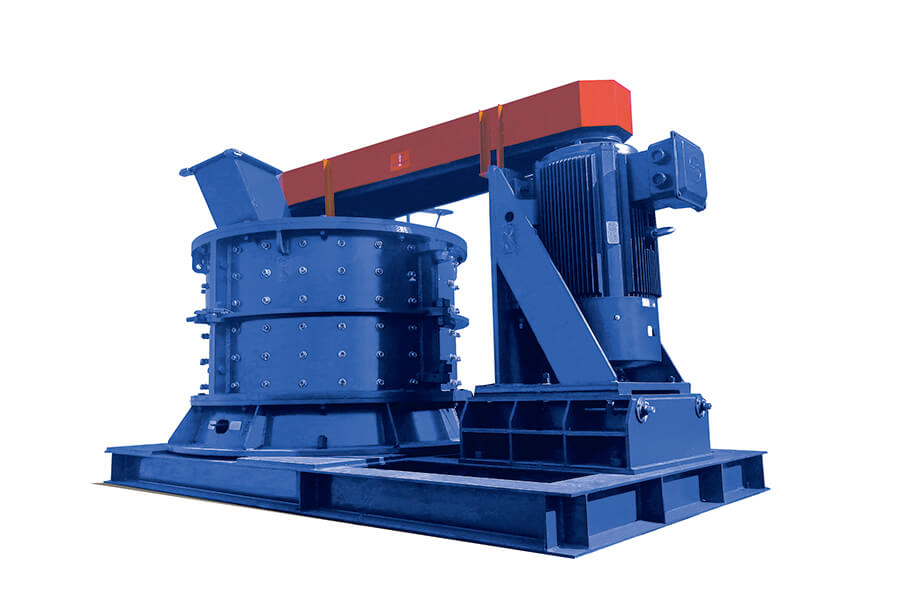

ZSL Series Compound sand making machine

It is an ideal fine crushing equipment developed for cement plant and new building materials industry.

It can be applied to cement raw meal, clinker and crushing of soft rock with medium hardness. Such as limestone, gypsum, coal gangue, etc. The equipment has the characteristics of large crushing wall, low energy consumption, simple structure, convenient operation and maintenance, etc.

Machine construction

Transmission device, main shaft, cylinder, upper cover, base and other main components.

Working Principle

The stone falls into the throwing plate of the crushing chamber from the feed hopper, and the material is thrown to the inner wall with the help of high-speed centrifugal force, which collides violently with the counterattack lining plate on the inner wall, so as to achieve the primary crushing effect of stone beating. Then, the material enters the conical rotor cavity, and with the help of the inclination angle between the rotor and the lining plate, the smaller material is forced to slide down, so as to achieve graded and segmented crushing from large to small. The material is hit by the hammer in the conical rotor cavity, the plate hammer and the material collide with the counterattack lining plate, and the stones collide with each other. Extrusion for secondary and tertiary crushing, so as to improve the crushing efficiency.

Video

Product Parameter

|

Model |

Input size (mm) |

Output size (mm) |

Speed (r/min) |

Throughput (t/h) |

Power(KW) |

Overall dimension (LxWxH) (mm) |

|

|

ZSL-1250II |

≤150 |

≤3 |

70-90% |

510-700 |

30-45 |

90 |

3130x`730x1840 |

|

ZSL-1500II |

≤180 |

≤3 |

70-90% |

430-640 |

50-70 |

132 |

3530x2050x2200 |

|

ZSL-1750II |

≤200 |

≤3 |

70-90% |

490 |

70-100 |

160 |

3820x2370x2300 |

|

ZSL-2000II |

≤220 |

≤3 |

70-90% |

455 |

90-120 |

200 |

4300x2610x2450 |

|

ZSL-2300II |

≤250 |

≤3 |

70-90% |

330-450 |

120-160 |

250 |

4470x2980x2554 |

|

Model |

Input size (mm) |

Output size (mm) |

Speed (r/min) |

Throughput (t/h) |

Power(KW) |

Overall dimension (LxWxH) (mm) |

|

|

ZSL-1250II |

≤150 |

≤3 |

70-90% |

510-700 |

30-45 |

90 |

3130x`730×1840 |

|

ZSL-1500II |

≤180 |

≤3 |

70-90% |

430-640 |

50-70 |

132 |

3530x2050x2200 |

|

ZSL-1750II |

≤200 |

≤3 |

70-90% |

490 |

70-100 |

160 |

3820x2370x2300 |

|

ZSL-2000II |

≤220 |

≤3 |

70-90% |

455 |

90-120 |

200 |

4300x2610x2450 |

|

ZSL-2300II |

≤250 |

≤3 |

70-90% |

330-450 |

120-160 |

250 |

4470x2980x2554 |