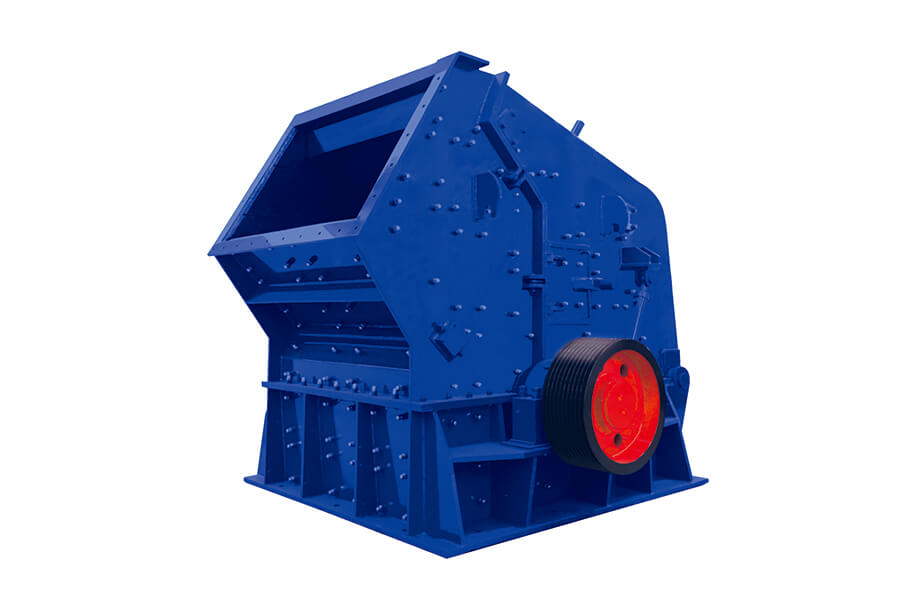

PF Series Impact Crusher

With new manufacturing process and special structural design, the processed products are cubic, tension-free and crack free, and the particle type is quite good. It can crush all kinds of coarse, medium and fine materials (limestone, concrete, etc.) with feed particle size not exceeding 300-700mm and compressive strength not exceeding 350Mpa. The discharge particle size can be adjusted and the crushing specifications are diversified.

Working Principle

PF series impact crusher uses impact energy to crush materials. During operation, driven by the motor, the rotor rotates at a high speed. When the material enters the plate hammer action area, it collides with the plate hammer on the rotor and is crushed again, and then thrown to the impact device, and then bounced back from the impact lining plate to the plate hammer action area for re crushing. This process is repeated. The material enters the first, second, third and impact chambers from large to small for repeated crushing, Until the material is crushed to the required particle size, it is discharged from the discharge port. Adjusting the gap between the counterattack frame and the rotor can change the discharge particle size and shape of materials.

Advantages

1. The feeding port is large and the crushing chamber is high. The heavy rotor is adopted and the finite element force analysis is carried out. The moment of inertia is larger, which makes the equipment have a larger crushing ratio and improves the crushing capacity of the equipment

2. The gap between the counterattack plate and the plate hammer can be flexibly adjusted. Through the design of the grinding chamber, the discharge particle size can be controlled, with good particle shape and low stone powder content

3. The utility parts are made of high chromium materials and practical materials. After strict heat treatment, they have good impact resistance and practical performance, so as to prolong the service life of the equipment and practical parts

4. Two sets of hydraulic flip devices are installed on both sides of the rack, which can facilitate users to easily open the rack and replace parts. The plate hammer locking device makes the replacement of the plate hammer more simple, convenient and fast

5. The product has strong universality. On the basis of not replacing other parts, the two chamber crushing equipment can be changed into three chamber crushing equipment by adding grinding frame, so as to reduce the secondary investment of users

6. The standardized design of lining plate has strong interchangeability, reducing the types and inventory of user spare parts, so as to reduce customer investment

7. Static and dynamic balance tests shall be conducted before rotor assembly. The main shaft is finished with excellent forgings, and the forward expansion sleeve tension connection mode is adopted to make the equipment operation more reliable

8. The overload and iron passing protection device is optimized. When the counterattack breaking exceeds its own load, the device can timely adjust the gap between the counterattack plate and the discharge port to prevent the equipment from shutdown due to overload

Product Parameter

|

Model |

Rotor (MM) |

Feed opening(MM) |

Max. feed size(MM) |

Capacity (T/H) |

Power (KW) |

Dimension (MM) |

|

PF-1007 |

Ø1000x700 |

400x730 |

250 |

15-60 |

55 |

2440x1580x2672 |

|

PF-1010 |

Ø1035x1050 |

400x1080 |

300 |

50-90 |

75 |

2650x2150x2900 |

|

PF-1210 |

Ø1250x1050 |

400x1080 |

300 |

70-130 |

110 |

2800x2150x2900 |

|

PF-1214* |

Ø1250x1400 |

400x1430 |

300 |

90-180 |

132 |

2850x2400x2900 |

|

PF-1315* |

Ø1320x1500 |

860x1520 |

350 |

120-250 |

220 |

3100x2800x3160 |

|

PF-1318* |

Ø1320x1500 |

880x2000 |

350 |

150-260 |

250 |

3100x3210x2613 |

|

PF-1320* |

Ø1320x2000 |

900x2030 |

500 |

160-350 |

315 |

3320x3218x2613 |

|

PF-1520* |

Ø1512x2000 |

1315x2040 |

700 |

350-450 |

400 |

4138x3422x3649 |

|

PF-1620* |

Ø1612x2000 |

1315x2040 |

700 |

400-600 |

450 |

4236x3572x3735 |

|

PF-1820* |

Ø1800x2000 |

1620x2040 |

700 |

550-800 |

630 |

4471x3250x4008 |

Models with * are available with two cavities and three cavities

1. The feeding port is large and the crushing chamber is high. The heavy rotor is adopted and the finite element force analysis is carried out. The moment of inertia is larger, which makes the equipment have a larger crushing ratio and improves the crushing capacity of the equipment

2. The gap between the counterattack plate and the plate hammer can be flexibly adjusted. Through the design of the grinding chamber, the discharge particle size can be controlled, with good particle shape and low stone powder content

3. The utility parts are made of high chromium materials and practical materials. After strict heat treatment, they have good impact resistance and practical performance, so as to prolong the service life of the equipment and practical parts

4. Two sets of hydraulic flip devices are installed on both sides of the rack, which can facilitate users to easily open the rack and replace parts. The plate hammer locking device makes the replacement of the plate hammer more simple, convenient and fast

5. The product has strong universality. On the basis of not replacing other parts, the two chamber crushing equipment can be changed into three chamber crushing equipment by adding grinding frame, so as to reduce the secondary investment of users

6. The standardized design of lining plate has strong interchangeability, reducing the types and inventory of user spare parts, so as to reduce customer investment

7. Static and dynamic balance tests shall be conducted before rotor assembly. The main shaft is finished with excellent forgings, and the forward expansion sleeve tension connection mode is adopted to make the equipment operation more reliable

8. The overload and iron passing protection device is optimized. When the counterattack breaking exceeds its own load, the device can timely adjust the gap between the counterattack plate and the discharge port to prevent the equipment from shutdown due to overload

|

Model |

Rotor (MM) |

Feed opening(MM) |

Max. feed size(MM) |

Capacity (T/H) |

Power (KW) |

Dimension (MM) |

|

PF-1007 |

Ø1000×700 |

400×730 |

250 |

15-60 |

55 |

2440x1580x2672 |

|

PF-1010 |

Ø1035×1050 |

400×1080 |

300 |

50-90 |

75 |

2650x2150x2900 |

|

PF-1210 |

Ø1250×1050 |

400×1080 |

300 |

70-130 |

110 |

2800x2150x2900 |

|

PF-1214* |

Ø1250×1400 |

400×1430 |

300 |

90-180 |

132 |

2850x2400x2900 |

|

PF-1315* |

Ø1320×1500 |

860×1520 |

350 |

120-250 |

220 |

3100x2800x3160 |

|

PF-1318* |

Ø1320×1500 |

880×2000 |

350 |

150-260 |

250 |

3100x3210x2613 |

|

PF-1320* |

Ø1320×2000 |

900×2030 |

500 |

160-350 |

315 |

3320x3218x2613 |

|

PF-1520* |

Ø1512×2000 |

1315×2040 |

700 |

350-450 |

400 |

4138x3422x3649 |

|

PF-1620* |

Ø1612×2000 |

1315×2040 |

700 |

400-600 |

450 |

4236x3572x3735 |

|

PF-1820* |

Ø1800×2000 |

1620×2040 |

700 |

550-800 |

630 |

4471x3250x4008 |

Models with * are available with two cavities and three cavities